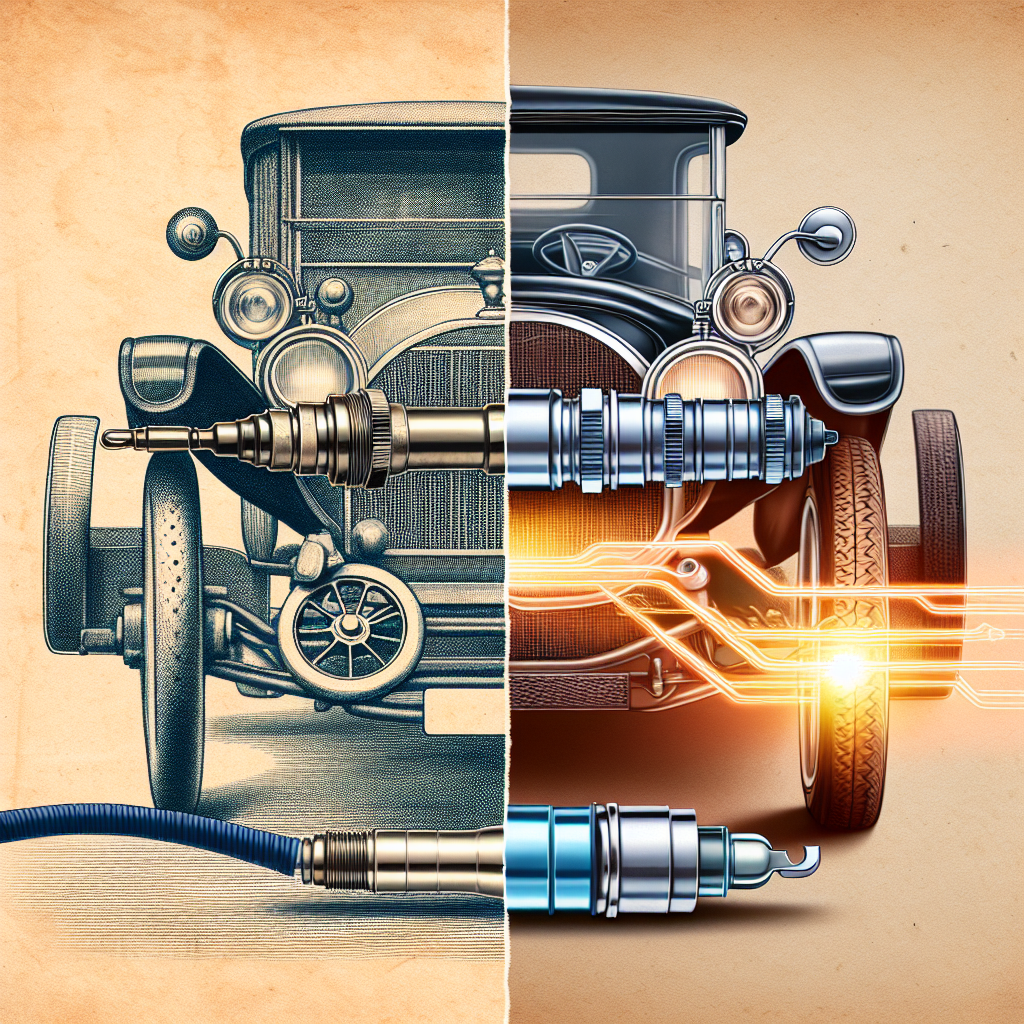

The journey of the ignition plug is a fascinating one, reflecting the broader evolution of automotive technology. From the dawn of the internal combustion engine to the rise of electric vehicles (EVs), ignition plugs have undergone significant transformations, adapting to the ever-changing demands of automotive engineering.

In the early days of motoring, ignition systems were relatively rudimentary. The first spark plugs were bulky, often unreliable, and demanded frequent maintenance. They consisted of a central electrode, an insulating material, and a ground electrode, but the materials used were less advanced. Copper was primarily employed for its excellent conductivity, while porcelain provided insulation.

As automotive technology advanced, so did the materials and design of ignition plugs. The introduction of platinum and iridium in the electrodes marked a significant leap forward. These metals drastically increased the lifespan of spark plugs and enhanced performance. Platinum and iridium could withstand higher temperatures and resist erosion better than copper, making them ideal for modern high-performance engines. Improved insulation materials also played a role in increasing durability and efficiency, leading to less frequent replacements and better combustion.

The shift toward increasing engine efficiency and reducing emissions prompted further innovations in ignition plugs. Manufacturers began to develop specialized plugs that catered to specific engine requirements. For instance, double platinum and iridium plugs offered superior longevity and spark efficiency, while specialized plugs for high-compression engines ensured reliable ignition under more demanding conditions.

In recent years, the automotive industry has seen a dramatic shift towards greener technologies and electric vehicles (EVs). While traditional internal combustion engines (ICEs) continue to benefit from ongoing advancements in ignition plug technology, EVs present a new set of challenges and opportunities. Ignition plugs are not completely obsolete in EVs, as range-extending hybrid vehicles still require efficient spark plugs. However, the role of ignition plugs is diminishing in pure electric drivetrains, signaling a transformative shift in automotive engineering.

Another intriguing development is the role of digital technology in ignition systems. Modern cars often rely on advanced Engine Control Units (ECU) that optimize ignition timing and enhance fuel efficiency. This has led to the development of Laser Ignition Systems, which utilize laser beams instead of traditional spark plugs. While still in experimental phases, laser ignitions promise higher precision, better fuel efficiency, and reduced emissions.

The secondary market for ignition plugs has also evolved significantly. As car enthusiasts and DIYers look to optimize their vehicles, aftermarket manufacturers have risen to meet this demand. High-performance spark plugs, including those with various heat ranges and gap configurations, offer tailored solutions for specific tuning needs. This customization allows vehicle owners to achieve desired performance characteristics, whether it be improved fuel economy, increased horsepower, or enhanced throttle response.

The evolution of ignition plugs is a testament to the relentless pursuit of automotive innovation. From the simple, maintenance-heavy spark plugs of yesteryears to the sophisticated, high-performance variants available today, they continue to play a crucial role in automotive performance. As the industry gravitates towards electric and hybrid technologies, the function of ignition systems may continue to evolve, but their legacy in driving automotive progress remains undeniable.

For more detailed insights and technical specifications on modern ignition plug varieties, AutoZone provides a comprehensive guide that can help you find the perfect match for your vehicle’s needs.